Head

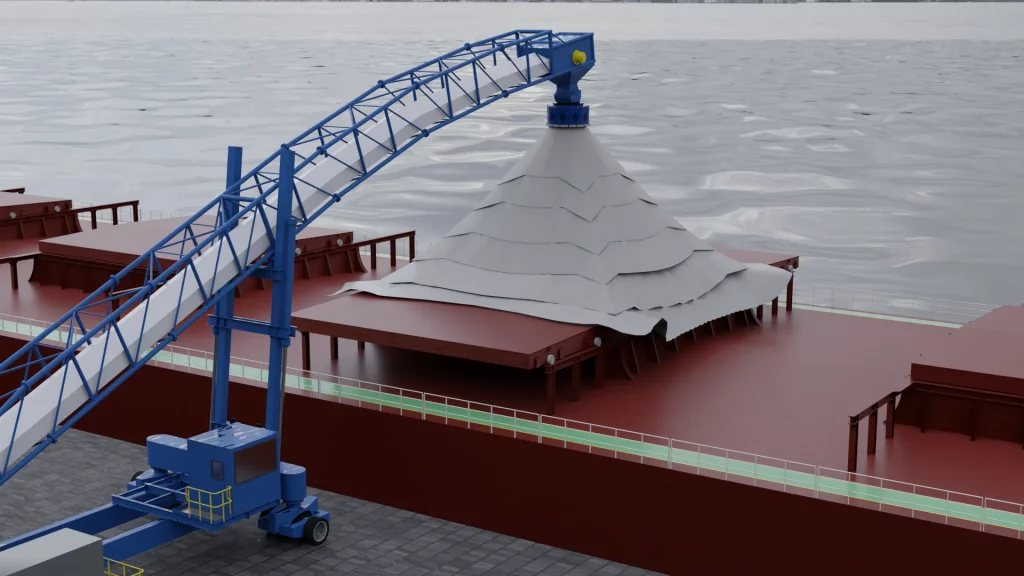

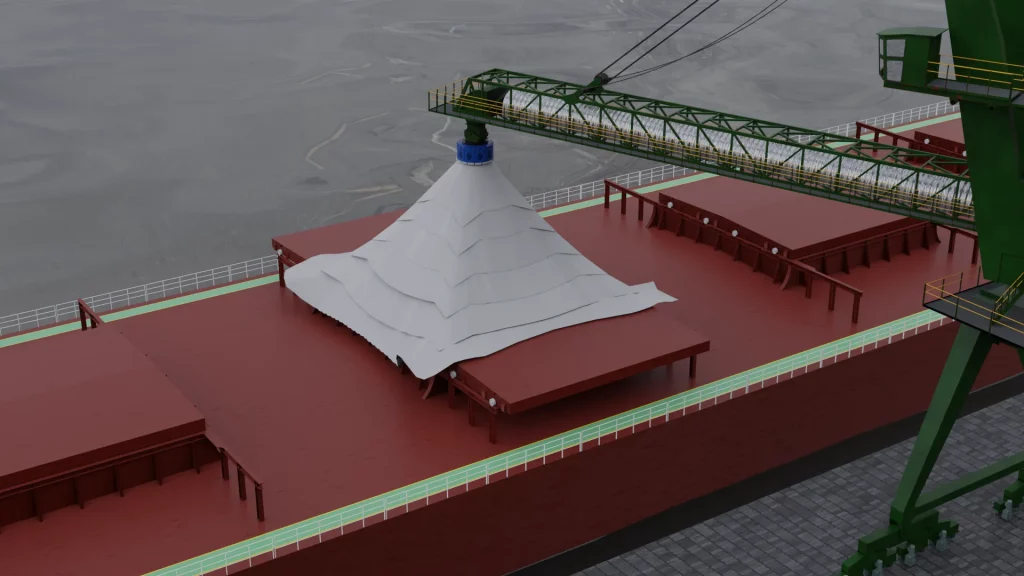

The head contains several motors that act as winches and are equipped with load sensors to keep cable tension constant. In addition, it has torque limiters to ensure the safety of the system, releasing the cable in case of overload and avoiding the risk of excessive forces on the supporting structure.

Cables

The cables are radially dispersed and run from the head to the hold cover. Because they are held in constant tension, they form a pyramidal structure that shapes itself according to the movements of the ship and the ship loader.

Springs

The springs are connected to the cables and form several concentric rings from the top to the bottom of the canopy. Their parameters are selected so that these spring rings are equidistant along the height.

Limiters

The limiters act to ensure that the springs will not separate by more than the width of the covers. In this way the covers form a continuous surface that protects the load during loading.

Covers

The covers are connected to the springs and form a surface for rain runoff. They are made of a special composite material that has different stiffness in both directions. This ensures wind and rain resistance while allowing Apluvia to adapt to different holds sizes.

Safety

Overload

protection

Systems are installed on each winch responsible for the cables that prevent these components from being overloaded. In this way the load transferred to the ship loader is limited, ensuring that the canopy and the loader are not overloaded.

Anti-static

protection

Apluvia’s cover is made entirely of antistatic materials, dissipating any possible generated charge. This ensures that operation with materials that generate explosive dust is extremely safe, as no sparks capable of initiating a combustion process are generated.

Loading

visualization

To ensure the correct filling of each hold, a 3D radar sensor is present transmitting the reading of the loading surface. Both the shiploader operator and the ship’s captain have access to this information, giving more credibility to the whole process.